Managing manufacturing operations becomes exponentially harder when a business deals with multiple product lines and thousands of product variants. What looks manageable at a small scale often turns into a daily struggle as demand grows and product complexity increases.

This was the reality for a growing manufacturing company producing configurable products across several categories. With slight differences in materials, routing, and processes for each variant, production planning slowly became chaotic. Manual tracking, disconnected tools, and limited visibility resulted in wasted raw materials, frequent delays, and teams spending more time managing data than producing goods.

The shift happened when the company adopted Odoo manufacturing ERP, bringing structure, visibility, and control back into its production operations without disrupting how the business actually worked.

The Reality of Multi-Variant Manufacturing Complexity

In multi-variant manufacturing environments, complexity doesn’t come from volume alone. It comes from variation.

This company managed:

- Thousands of SKUs under shared product templates

- Product variants with minor BOM differences

- Frequent changes in materials or components

- Parallel production workflows across product lines

Without a centralized ERP for manufacturing companies, the production team relied heavily on spreadsheets and local software. Information was scattered, and planning decisions were often based on outdated or incomplete data.

The result was predictable:

- Incorrect BOM selection during production

- Excess material consumption and avoidable scrap

- Poor coordination between sales, inventory, and production

- Limited traceability once production started

The lack of real-time insight made multi-variant manufacturing processes inefficient, reactive, and costly.

Why Manual Systems and Traditional ERP Fell Short

Before implementing Odoo, the company attempted to adapt its processes to rigid ERP systems and manual workarounds. Neither approach delivered sustainable results.

Traditional manufacturing ERP platforms often struggle to support:

- Flexible product variant structures

- Frequent engineering or BOM changes

- Real-time shop floor visibility

- Scalable customization without heavy cost or complexity

Manual systems, while flexible, offered little control. Production planning took hours, sometimes days. Errors were often discovered only after materials were already consumed.

What the company needed was a scalable ERP for manufacturers, one capable of handling growing complexity without slowing down operations.

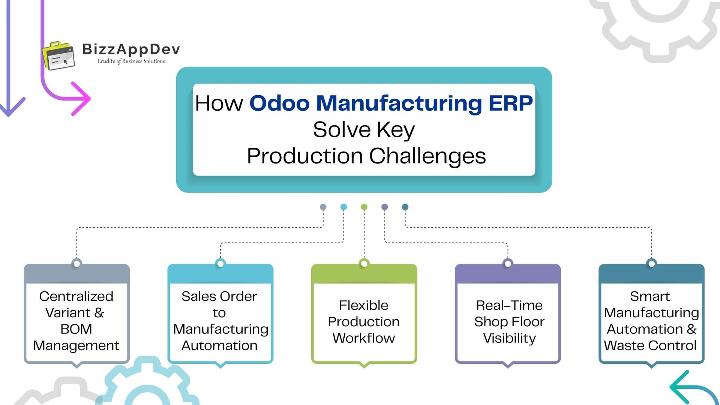

How Odoo Manufacturing ERP Addressed These Challenges

The implementation of Odoo manufacturing ERP focused on solving real operational problems, not simply replacing one system with another.

Instead of forcing standardized workflows, Odoo adapted to the company’s existing production practices and improved them through centralized data, process consistency, and better visibility.

Centralized Variant & BOM Management

One of the most impactful improvements came from Odoo bill of materials management combined with product variant handling.

Odoo enabled the company to:

- Use a single BOM for multiple variants where applicable, reducing duplication

- Apply variant-specific rules without creating separate BOMs for every SKU

- Maintain alternative BOMs for different production scenarios

- Manage engineering changes without disrupting active manufacturing orders

With Odoo variant management, production teams no longer needed to manually verify materials for each order. This significantly reduced errors and improved material control.

For manufacturers handling Odoo configurable products or customized assemblies, this centralized approach is critical for maintaining accuracy at scale.

Sales Order to Manufacturing Automation

Previously, sales and production operated in silos. Confirmed orders often took days to reflect in production plans.

With Odoo, the sales order to manufacturing order flow became seamless. Once a sales order was confirmed:

- Manufacturing orders were generated based on configured routes

- Variant-specific BOMs were automatically applied

- Inventory availability was checked in real time

This demand-driven approach improved inventory and production alignment, reduced overproduction, and allowed the company to respond faster to customer demand.

With guidance from experienced Odoo implementation partners, procurement rules and routes were configured to match real-world production strategies.

Flexible Production Workflow

Production teams often resist ERP systems that feel restrictive. Odoo addressed this concern by supporting a configurable Odoo production workflow that reflected actual shop floor operations.

The company implemented:

- Multi-step routings

- Automated work order generation based on defined routes and production rules

- Clear task definitions for operators and supervisors

While Odoo automated repetitive administrative tasks, supervisors retained full control to adjust workflows when required. This balance improved process consistency without limiting operational flexibility.

Real-Time Shop Floor Visibility

Lack of shop floor visibility had been one of the company’s biggest operational challenges.

With Odoo shop floor management, supervisors were able to:

- Monitor work order status in real time

- Identify bottlenecks early in the production cycle

- Track operator progress directly through the shop floor interface

Operators updated work orders using tablets or terminals, improving the reliability of Odoo production tracking.

This real-time visibility allowed faster decision-making and reduced delays across production lines.

Smart Manufacturing Automation & Waste Control

Rather than eliminating wastage automatically, Odoo helped the company identify where wastage was occurring and why.

Through Odoo manufacturing automation, the system tracked:

- Planned versus actual material consumption

- Scrap quantities at each stage of production

- Quality checks integrated within manufacturing workflows

These insights enabled production managers to take corrective actions, refine processes, and improve accountability. Over time, this data-driven approach helped teams continuously improve production efficiency and reduce avoidable losses.

Measurable Business Impact After Odoo Adoption

Within months of adopting Odoo, the company experienced clear and measurable improvements:

- Reduced raw material wastage

- Faster and more reliable production planning

- Improved on-time order fulfillment

- Better traceability across all production stages

- Easier onboarding of new product variants

Most importantly, the system scaled as the business grew. New product variants could be introduced without restructuring the entire production setup.

Why Odoo Fits Complex Manufacturing Environments

Odoo stands out as an ERP solution for multi-product manufacturing companies because it combines flexibility with operational control.

Key advantages include:

- Modular design that grows with the business

- Strong support for variant-heavy manufacturing

- Integrated quality, inventory, and production modules

- Cost-effectiveness compared to legacy ERP platforms

With tailored Odoo customization services, manufacturers can adapt workflows and reporting to their needs without compromising system stability.

Odoo vs Traditional Manufacturing ERP Systems

When evaluated through a manufacturing ERP software comparison, Odoo offers clear advantages:

- Superior handling of product variants

- Flexible and centralized BOM management

- Built-in automation without expensive add-ons

- Intuitive user experience for shop floor teams

For manufacturers seeking ERP for operational efficiency, Odoo delivers enterprise-level capabilities with far greater adaptability.

Is Odoo Manufacturing ERP Right for Your Business?

Odoo is well suited for manufacturing companies that:

- Manage large volumes of product variants

- Struggle with production visibility and coordination

- Depend on manual planning or disconnected tools

- Need a scalable solution to support growth

As a cost-effective ERP for manufacturing operations, Odoo supports both short-term stability and long-term expansion.

Final Thoughts: Turning Manufacturing Complexity into Control

Multi-variant manufacturing will always involve complexity, but it does not have to be unmanageable.

By adopting Odoo manufacturing ERP, this company moved from reactive problem-solving to proactive production control. Centralized variant management, real-time visibility, and data-driven insights enabled teams to reduce waste, improve efficiency, and scale with confidence.

For manufacturers facing similar challenges, Odoo offers a practical and flexible path toward operational clarity, without forcing the business to compromise how it works.

Turn manufacturing complexity into operational control.

Discover how Odoo Manufacturing ERP helps manage variants, reduce waste, and improve production visibility. Request a demo today.

FAQs

Odoo manages multiple product variants using shared templates and flexible BOM rules. This allows manufacturers to control thousands of variants without duplicating data or increasing production complexity.

Yes. Odoo allows manufacturers to update BOMs and components without disrupting ongoing production. Alternative BOMs help manage engineering changes smoothly and accurately.

Odoo automatically links confirmed sales orders to manufacturing orders. This ensures production planning is aligned with real demand, reducing delays and manual coordination.

Yes. Odoo offers real-time work order tracking through shop floor interfaces, helping supervisors monitor progress, identify bottlenecks, and make faster production decisions.

Odoo tracks planned versus actual material usage and scrap at each stage. This visibility helps manufacturers identify wastage early and improve production efficiency.

Odoo is ideal for growing manufacturers due to its modular design, scalability, and strong support for product variants and complex production workflows.